Jiangsu Taishun Energy Technology Development Co., Ltd. is a manufacturer specialize in API 5CT tubing or seamless tubing, casing, pup joints, crossovers, tubing couplings and casing couplings

|

||||||||||

API Products Perfection links & Drill collar lift adaptor Rotary slips & Casing slips & Drill collar slips

Related information |

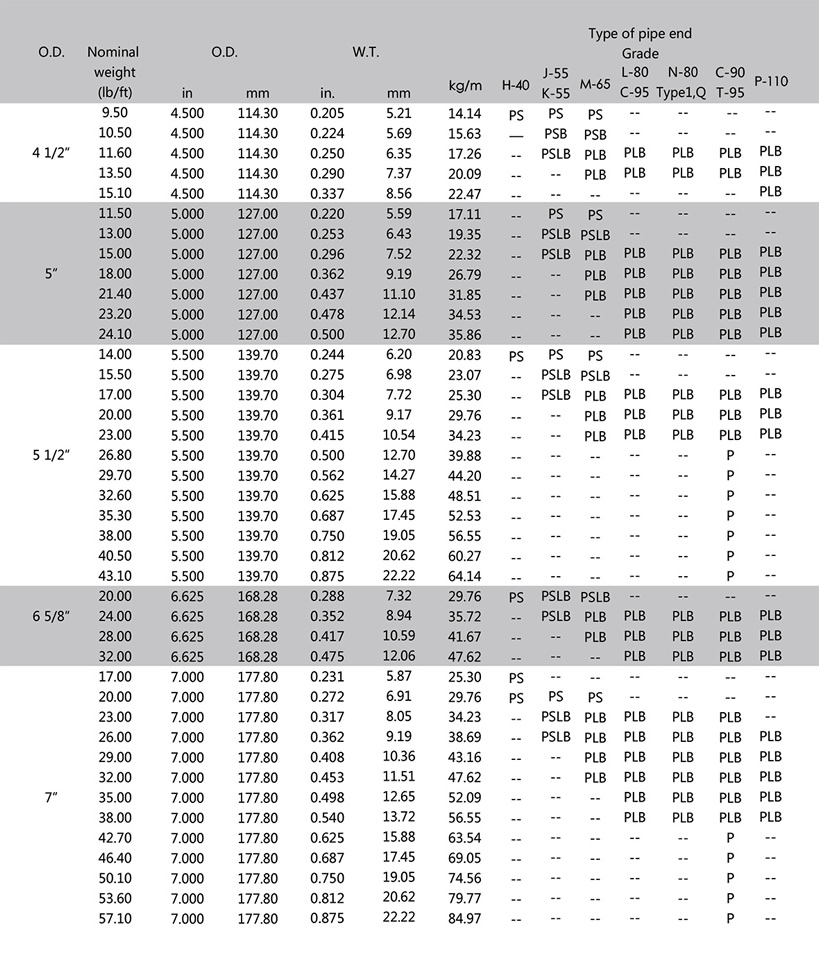

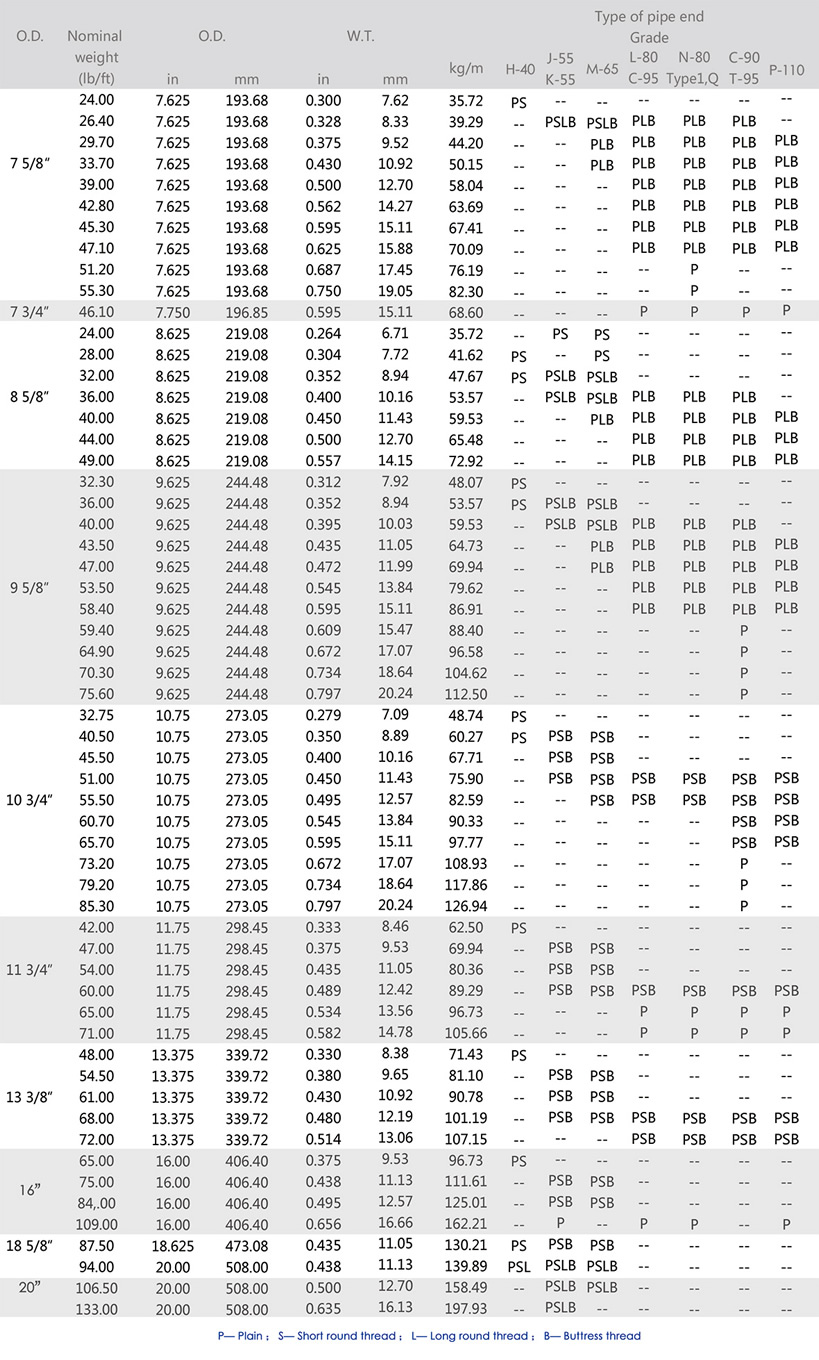

API 5CT Casing API 5CT Casing is a large-diameter steel tube that serves as the structural retainer for the walls of oil and gas wells, or wellbore. The casing pipe is inserted into a well bore and cemented in place to protect both subsurface formations and the wellbore from collapsing and to allow drilling fluid to circulate and extraction to take place. The following diagram illustrates different types of casing used in the extraction process: Surface casing: a. It protects the well from contamination in shallow water and gas layers. b. Supports the wellhead equipment and sustains the weight of the other layers of casing. Intermediate casing: a. Isolates different layers of pressure to facilitate normal circulation of drilling fluid and protect the production casing. b. Intermediate casing facilitates the installation of blow-out preventers, anti-leakage devices and tailpipes in the well. Production casing (oil string) a. It is the conduit through which oil and gas pass from a below surface reservoir. b. It protects the well and separates fluids into various layers. For the manufacture of tubing pipe, green steel tubes undergo an "upsetting" process to thicken the walls of the pipes. Apart from this step, the manufacturing of tubing pipes and casing pipes are identical. First, green steel tubes are threaded on each end. The threading is then inspected and, if necessary, rethreaded to ensure that the thread accurately connects to the coupling. The tubing and casing pipes are strengthened by surface treatment and are subject to various inspections, including drifting and hydrostatic tests before they are coated and packaged into tubing and casing pipes. Some specifications of the API 5CT steel tube: 1) Standard: API SPEC 5CT 2) Usage: Casing is used as walls of the well 3) Casing pipes are ordinarily produced with outside diameter sizes of 114.3 mm to 339.73 mm. Casing Product

Casing Specification

|

|||||||||